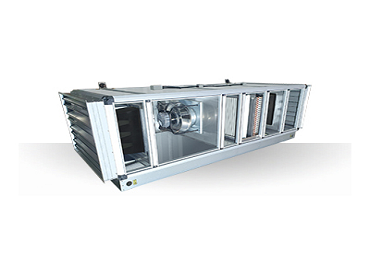

Maven Trading and Services WLL provides Hygienic AHU’s from Trosten. Tested by TUV lab in Germany, these units meet DIN 1946 Part 4:2008 and VDI 6022 Part 1: 2011 Standards. Different configurations are offered with various types of heat recovery choices like Heat Pipe heat recovery & Run around coils and Recuperator. Components like HEPA Filter, UVC lamp, plug fans, EC fans can be provided. Hygiene Air Handling Units are made from snap-fix (screwless) casing technology, providing a smooth finish for the ease of cleaning the internal surfaces. Filters are in accordance with ISO16890. Microbial inertness is compiled in accordance with ISO 846 for nylon and gasket parts and VOC free Coil coating. Main applications in pharmaceutical industries, Surgical Operating Rooms, Isolation Rooms and Food Processing Industries.

Hygienic Air Handling Unit

Hygienic Air Handling Unit

IMPORTANT FEATURES

- The range of Capacity is 600 CFM to 60000 CFM.

- TUV-SUD, Germany has tested and approved Hygienic Air Handling Units per DIN 1946 Part 4:2008 and VDI 6022 Part 1:2011 standards.

- The snap fix (screw-less) panel construction and aluminum or stainless-steel sheet casing.

- All fasteners and hardware must be made of stainless steel.

- The drainpan should be made of SS 316 stainless steel.

- Directly powered plug-in or EC fans.

- Options for heat recovery include run-around coils, heat pipes, plate type heat exchangers, and more.

- The plastic components and gaskets utilized must meet ISO846 standards for microbiological inertness.

- Major parts, such as fans, motors, coils, etc., must be removable.

- Options such as Hepa filters and UV lamps are available.